Innovative AR/VR Integration for Manufacturing

Project Overview:

MindCrew Technologies collaborated with InnovateTech Manufacturing, a leader in industrial machinery production, to create an advanced AR/VR solution. The aim was to transform their design, visualization, and training processes by leveraging cutting-edge augmented reality (AR) and virtual reality (VR) technologies. This project was designed to provide immersive experiences for their design engineers and trainees, ultimately improving efficiency and reducing costs.

Business Needs:

InnovateTech faced several challenges with their existing processes:

- Design Complexity: Traditional design methods were labor-intensive and prone to errors, resulting in delays and increased costs.

- Training Efficiency: Training new employees on complex machinery was time-consuming and required significant resources.

- Prototyping Costs: The high cost and time associated with physical prototyping were major bottlenecks in their product development cycle.

- Collaboration Barriers: The lack of an interactive and immersive environment hindered effective collaboration among design teams.

To address these issues, InnovateTech required a solution that could:

- Enhance the accuracy and speed of the design process.

- Provide immersive, hands-on training experiences.

- Reduce prototyping costs through virtual testing.

- Improve collaboration across design teams.

Technical Needs:

The technical requirements for the solution included:

- AR/VR Integration: The application needed to seamlessly integrate AR/VR technologies to create immersive environments.

- Real-Time Rendering: High-performance rendering capabilities to handle complex 3D models in real-time.

- Compatibility: Integration with existing CAD software and manufacturing systems for easy data transfer and manipulation.

- Data Security: Robust security measures to protect sensitive design data and ensure compliance with industry standards.

Solution:

Immersive Design Review:

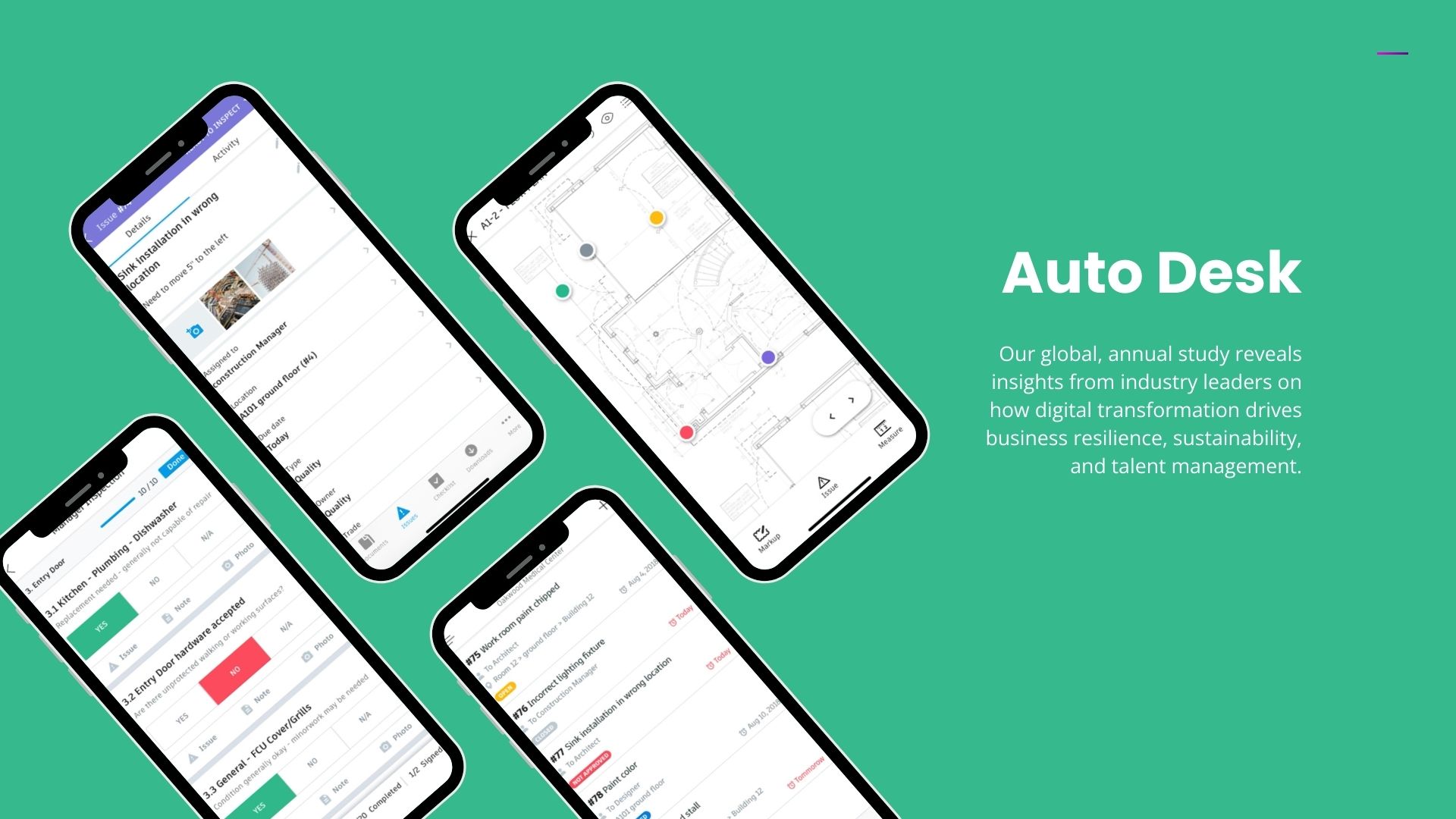

- Virtual Reality Visualization: Designers and engineers could use VR headsets to visualize and interact with 3D models of machinery in a virtual space. This allowed for detailed inspections, real-time modifications, and enhanced spatial understanding of designs.

- Interactive Prototyping: The VR environment enabled virtual prototyping, allowing users to test and refine designs before creating physical prototypes. This significantly reduced the time and cost associated with the prototyping phase.

Augmented Reality Training:

- AR Instructional Overlays: Trainees could use AR devices to view digital overlays on real-world machinery. These overlays provided step-by-step instructions and guidance, making complex procedures easier to understand and execute.

- Simulated Training Scenarios: AR was used to create realistic training scenarios, enabling trainees to practice and master their skills in a controlled, risk-free environment.

Seamless Integration:

- CAD Integration: The application was fully integrated with InnovateTech’s existing CAD software, allowing for easy import, manipulation, and visualization of 3D models.

- Data Synchronization: Real-time synchronization with the manufacturing systems ensured that design changes were immediately reflected across all platforms, maintaining consistency and accuracy.

High-Performance Rendering:

- Advanced Graphics Engine: Utilized cutting-edge graphics technology to ensure smooth and realistic rendering of complex 3D models, providing a high-quality visual experience.

- Real-Time Interaction: Enabled real-time interaction with 3D models, allowing users to make and view changes instantaneously.

Data Security:

- Encryption and Compliance: Implemented robust encryption protocols and adhered to industry regulations (such as GDPR) to ensure the protection of sensitive design data.

- Access Controls: Strict access controls were put in place to prevent unauthorized access and ensure that only authorized personnel could view and modify the data.

Impact:

The implementation of the AR/VR solution had a profound impact on InnovateTech’s operations:

- Increased Design Efficiency: Design accuracy improved by 30%, and the design review process was cut in half. Engineers could identify and resolve issues early in the design phase, reducing rework and delays.

- Enhanced Training Effectiveness: Training time for new employees was reduced by 40%, with trainees demonstrating higher retention and understanding of complex procedures. The interactive and hands-on training approach led to better-prepared employees.

- Cost Savings: InnovateTech reported a 25% reduction in prototyping costs. Virtual prototyping allowed for thorough testing and refinement of designs before committing to physical prototypes, saving both time and resources.

- Improved Collaboration: The immersive VR environment facilitated better collaboration among design teams, fostering innovation and creativity. Team members could work together in a virtual space, regardless of their physical locations.

Client Review:

“The AR/VR solution developed by MindCrew Technologies has revolutionized our design and training processes. The ability to visualize and interact with our products in a virtual space has greatly improved our efficiency and accuracy. Additionally, the immersive training tools have significantly reduced the time and cost associated with onboarding new employees. We are extremely satisfied with the results and look forward to continuing our partnership with MindCrew Technologies.” – Adam john